India’s space ambitions have always been about more than just reaching the stars — they represent innovation, engineering excellence, and a growing self-reliance in aerospace manufacturing. One of the key contributors to this journey is Kineco Aerospace, a homegrown composite manufacturing company that has quietly become a critical part of ISRO’s landmark missions.

Recently, Kineco Aerospace announced its participation in ISRO’s LVM3-CMS03 launch, underscoring its role in building high-performance composite structures that go into India’s most advanced rockets.

Kineco Aerospace’s Role in LVM3-CMS03

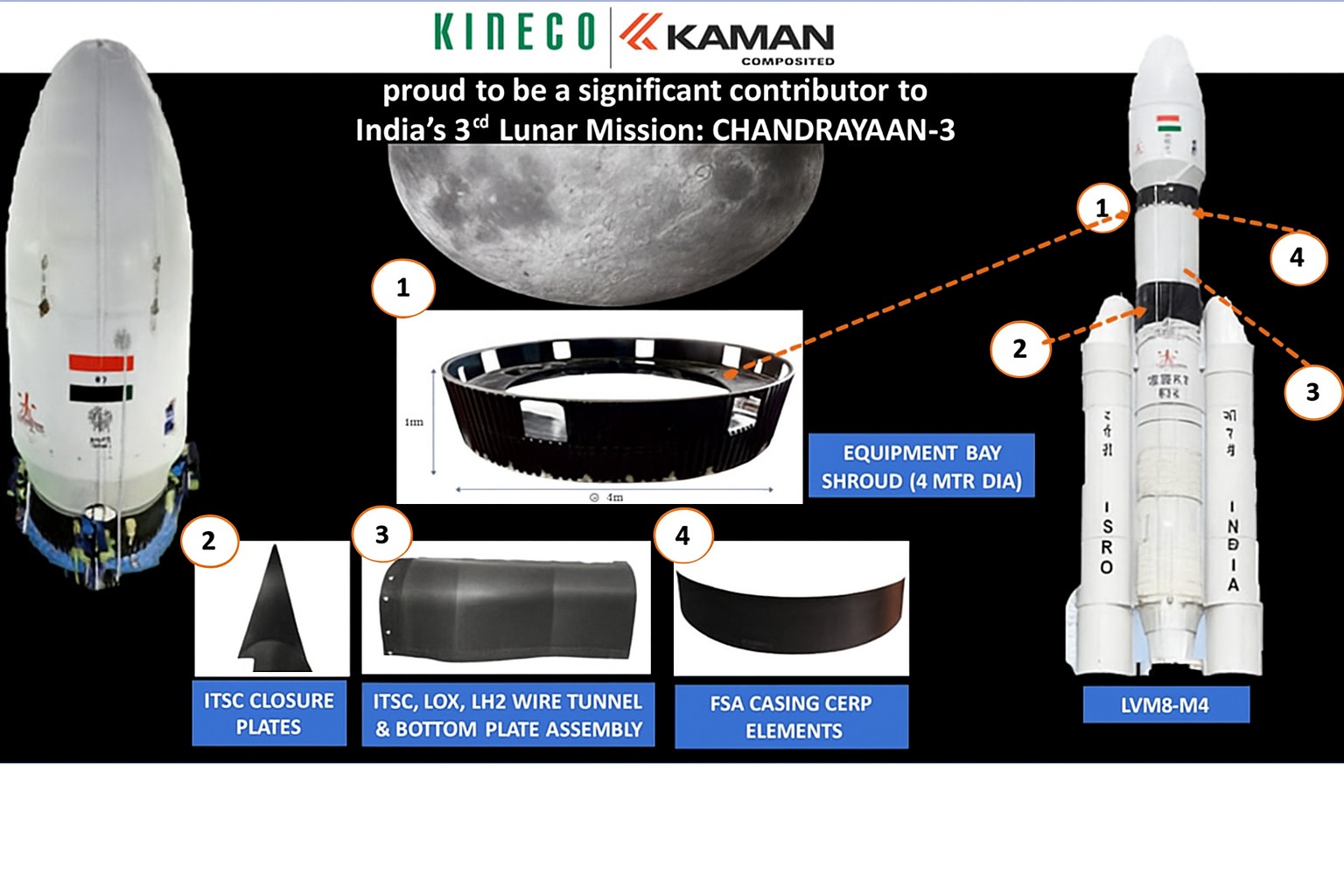

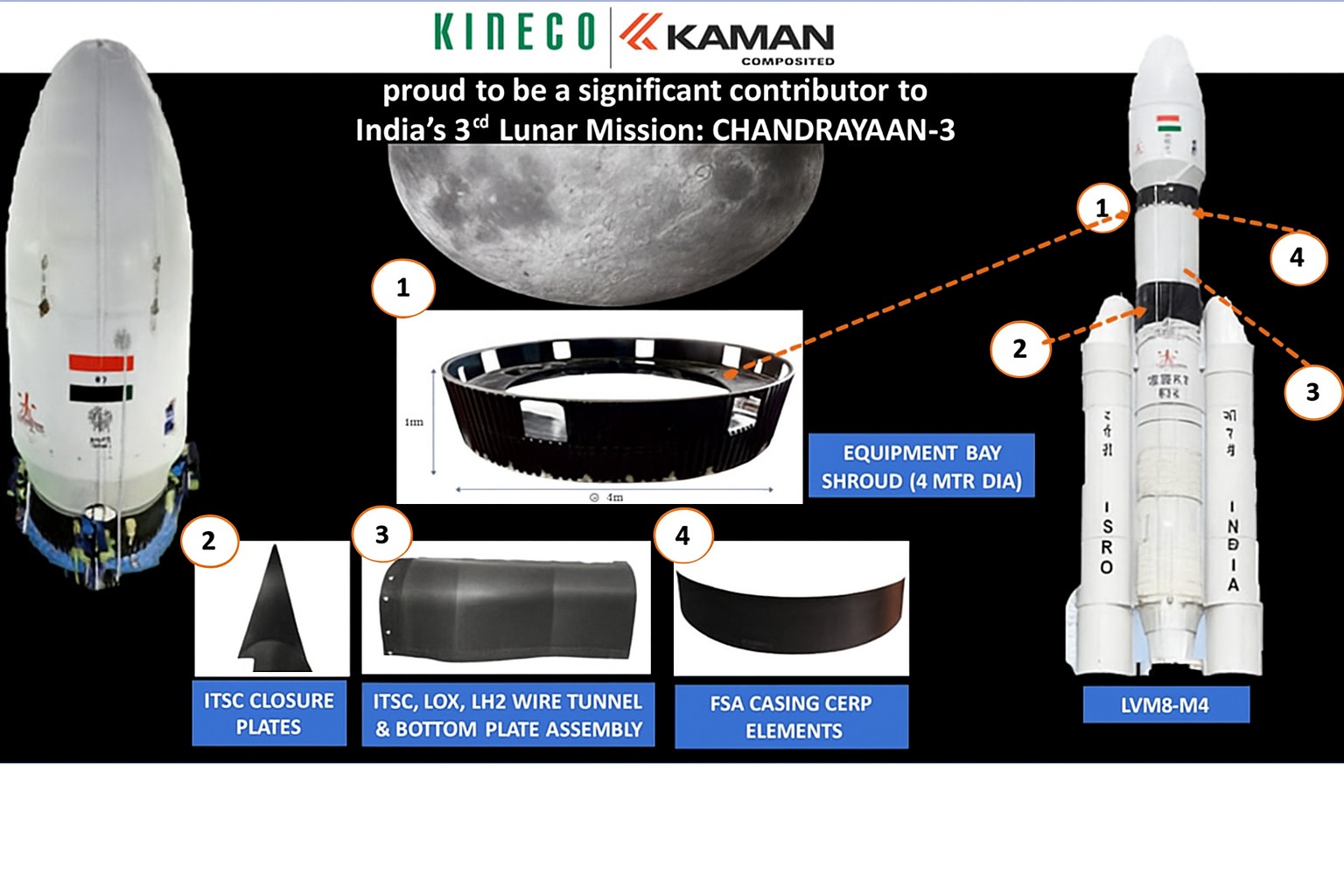

As part of the LVM3-CMS03 mission, Kineco delivered multiple mission-critical components made from advanced composite materials. These include:

1. 3rd Equipment Bay Shroud

A continuation of its earlier success in the OneWeb and Chandrayaan-3 missions, this shroud acts as a protective housing for electronic modules inside the rocket. It must withstand extreme vibration, pressure, and thermal conditions during launch and ascent.

2. Wire Tunnels & Bottom Plates (24-part set)

These are structural conduits that protect and route electrical wiring throughout the rocket. They ensure secure signal transmission between different systems in the launch vehicle.

3. ITSC Closure Plates (25-part set)

Critical to ensuring aerodynamic efficiency and structural sealing, these closure plates are used to join and seal various sections of the rocket body. Their failure is not an option, which makes precision in design and manufacturing absolutely vital.

Why Composite Structures Are So Important

Space-grade composites used by Kineco offer unique advantages:

-

Lightweight but strong: reduces the total payload weight.

-

Corrosion and fatigue resistance: perfect for enduring extreme space and launch conditions.

-

Thermal stability: handles temperature variations from -150°C to +120°C.

The combination of these factors helps ISRO increase payload capacity and mission reliability — both critical for successful space operations.

🇮🇳 Make in India — In Space Too

Kineco Aerospace’s success story is a prime example of the Make in India initiative working at a global scale. The company manufactures these high-precision assemblies in India, supporting not only ISRO but also private sector space programs and defence applications.

Their facility in Goa houses autoclaves, CNC machines, clean rooms, and QA labs that meet global aerospace standards. Over time, their capabilities have made them a preferred partner in India's space supply chain.

A Small Contribution with a Big Impact

While each individual part might seem small, their role in the larger mission is crucial. The LVM3 rocket, used for heavy satellite launches and planetary exploration, depends on each subsystem working in unison. Companies like Kineco help ensure that this unison is flawless.

In their own words:

“We are honored to play a small but significant role in India’s growing space journey.”

Congratulations to ISRO — And the Ecosystem

The successful launch of the LVM3-CMS03 mission is yet another feather in ISRO’s cap — but it’s also a proud moment for every supplier, technician, and engineer behind the scenes. Kineco Aerospace’s high-quality components showcase the synergy between Indian manufacturing and space technology, making this a team achievement for the nation.

🖼️ Visual: What Did Kineco Supply

What’s Next for Kineco?

With India’s Gaganyaan (human spaceflight), Venus missions, and more satellite constellations on the horizon, Kineco’s composite technology is expected to find a home in even more complex and demanding applications — positioning the company as an indispensable pillar in India’s space ecosystem.